PCB Assembly requires knowledge beyond just PCB components and assembly; it also requires expertise in printed circuit board design, layout, PCB fabrication, and applications of the final product. High quality PCB assembly services are a key piece of the puzzle required in delivering the perfect product to market the first time - without rework or assembly errors.

San Francisco Circuits is a one-stop solution for all circuit board production services - fabrication, testing/inspections, and assembly.

Our clients hire us to be their full or partial turn-key provider from manufacturing to assembly and testing. Through our strong network of well-proven partners, we can provide the most advanced and nearly limitless capabilities for your prototype or production PCB run.

Save yourself the trouble that comes with the procurement process and dealing with multiple components vendors. Our experts will find you the best parts for your final product.

Check out our PCB component overages "cheat sheet" to help you know how many of each component size need to be ordered and at what quantity.

| Capabilities | Testing Services |

|---|---|

| Small, medium, and high volume PCB assembly | X-Ray (2-D and 3-D) |

| Surface Mount Technology / Parts (SMT Assembly) | BGA X-Ray Inspection |

| Double-sided SMT | AOI Testing (Automated Optical Inspection) |

| Standard lead & lead-free builds (RoHS compliant) | ICT Testing (In-Circuit Testing) |

| Through-Hole Device / Parts (THD) | Functional Testing (at the board & system level) |

| Mixed Parts: SMT & THD assembly | Flying Probe |

| BGA / Micro BGA / uBGA/td> | |

| QFN, POP & lead-less chips/td> | Rework |

| 2800 pin-count BGA | BGA Rework & Repair |

| 0201 resistors / 1005 passive components | Engineering Rework |

| 0.3 / 0.4 Pitch | BGA Reballing |

| PoP Package | Board Debugging & Repair |

| Flip-chip under-filled CCGA | |

| BGA Interposer / Stack-up and more… | |

| High speed component placement with X-Ray verification | |

| Supply chain management |

Assembly without procurement

Turnkey Assembly (procurement+assembly)

The final lead time for a circuit board assembly order is procurement lead time plus assembly time.

On average, lead times are 1-5 days for assembly alone and 1-5 days for turnkey assembly.

If you have a design that requires fine pitch, a rush order or even the challenge of getting a hard-to-find component you have San Francisco Circuits, your PCB partner who is flexible and dependable for your most complicated needs.

Full & Partial Turnkey Assembly - Typical turnaround times:

| BOM Verification & Quoting | 2 business days from submission |

| Component Sourcing | 1-3 business days from order date (depending on availability) |

We offer both full turnkey PCBA and partial turnkey. Both options have similar concepts - they reduce your responsibility to source electronic components, including overage calculations, managing the BOM, logistics, inventory and more.

For full turn-key services, we manage and produce everything including manufacturing the circuit boards, finding & ordering PCB components, quality inspection & testing and the final product assembly. Our technical experts apply their knowledge to each order, whether it be a low volume PCB assembly prototype project or a large scale production run.

Sourcing components is often problematic. Coordinating lead times, component overages, part substitution logistics, multiple component vendors and your PCB assembly house is a big drain of energy and resources.

In addition, many quality control factors come into play with consigned assembly kits.

Full turnkey assembly includes the entire spectrum of services including:

Partial turnkey, on the other hand, allows customers to take control of one or more of the processes listed above. Typically, this would be sourcing and shipping some or all of the components (consignment or partial consignment).

The consignment assembly model is becoming less and less common due to the many benefits that come with full turnkey assembly.

In general, delegating all or part of the responsibility for component sourcing and assembly to us is beneficial for many reasons:

Typically, a full turnkey assembly will lead to a quicker delivery and more consistent end-products leading to a shorter time to market!

Components for surface mount assembly should be on tape and reel. Cut tape may also be used but only if there is sufficient tape to mount into the feeders.

Quantities & Overages

By far the most important factor for consigned PCB assembly is component quantities.

It is critical to provide the correct quantities, including overages, and ensure the count is correct when the components are shipped out (we cannot logistically count every single component).

Please refer to our component overages cheat sheet below for the quantity of spares needed on the tape to account for attrition:

| Quantity Needed | |||

|---|---|---|---|

| Component Size | Need less than 20 pieces | Need less than 50 pieces | Need less than 100 pieces |

| 01005 | Order 150 or more | Order 200 or more | Order 250 or more |

| 0201 | Order 100 or more | Order 150 or more | Order 200-250 or more |

| 0402 | Order 100 or more | Order 150 or more | Order 200-250 or more |

| 0603 | Order 100 or more | Order 150 or more | Order 200-250 or more |

| 0805 | Order 50 or more | Order 100 or more | Order 150 or more |

| 1206 | Order 50 or more | Order 100 or more | Order 150 or more |

The quantities required above would be for each set up of the feeder and remaining parts will be lost during the removal and reinstallation. So, if the assembly job is being set up more than one time or on future runs, additional components will be required.

View more details on our PCB component overages "cheat sheet" page.

Proper Identification in BOM & Kit

When submitting a consignment kit, it is important that the part numbers match the BOM, including any alternate part numbers.

Advanced Packages / BTCs (Bottom Terminated Components)

BGAs, QFNs and other similar components should be verified to the PCB footprint. Footprint errors that are found at placement cause difficulties as they would require a special reflow process (often with custom tooling) after initial population and reflow soldering and cannot be hand soldered.

Inspection of Consigned Bare Boards

If the bare circuit boards will also be consigned, a full inspection of the boards should have been done beforehand. While we will conduct a basic quality inspection of the circuit boards, a full inspection of items like fabrication notes, hole sizes, certifications and dimensions should be conducted by the customer.

Get professional advice on material selection, stack-up, copper weight, final finish, filled vias, stacked vias, blind and buried vias, drill to copper requirements, and much more.

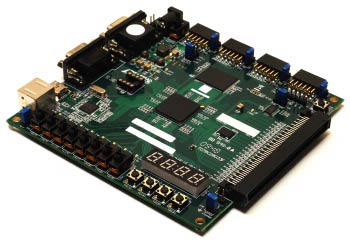

PCB prototyping has always been one of our most requested services, whether it’s PCB prototype fabrication or assembly. Our expert engineers will check and test your layout to ensure the correct prototype is fabricated and assembled on the first assembly run. Through our network of PCB component suppliers and SMT assembly engineers, we can ensure you a quick turn around and top quality circuit board. We offer low volume circuit assembly for prototyping with DFM and DFT to eliminate possible issues in your product.

.jpg)

Assembled Microwave RF / PCB

Call our circuit assembly experts at 800-SFC-5143 to make your concept into reality!