In today’s interconnected digital landscape, safeguarding sensitive information is not just a priority—it’s a necessity. For businesses engaged with U.S. government contracts, compliance with cybersecurity standards is essential to protect Controlled Unclassified Information (CUI). One critical framework for ensuring this is the National Institute of Standards and Technology (NIST) Special Publication 800-171, which outlines security requirements for protecting CUI within non-federal systems and organizations.

Image Credit: National Institute of Standards and Technology (nist.gov)

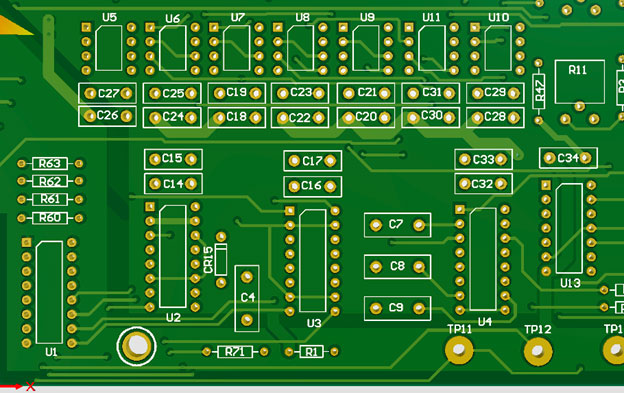

For PCB manufacturers, compliance with NIST 800-171 is increasingly significant, as the electronics industry often intersects with sensitive defense, aerospace, and other government-related sectors. Understanding the framework and its implications is vital for PCB manufacturers, as it ensures they can protect their customers' sensitive data, meet federal standards, and maintain their reputation as trusted suppliers in critical industries.

Likewise, for PCB buyers, ensuring your manufacturing and assembly partners are compliant with these cybersecurity guidelines is critical - whether it’s a government contract or not.

NIST 800-171 establishes guidelines to protect CUI—a classification for information that requires safeguarding (but is not classified) under national security. The directive provides a structured approach to ensure that non-federal organizations handling CUI can maintain its confidentiality.

First issued in 2015 and made mandatory for Department of Defense (DoD) contractors in 2017, NIST 800-171 is rooted in the Federal Information Security Management Act (FISMA) and aims to mitigate risks associated with cyberattacks, data breaches, and unauthorized access. The framework specifies 110 controls divided across 14 families of requirements, ranging from access control to system integrity.

The Department of Defense increasingly requires its suppliers to adhere to NIST 800-171 through its Defense Federal Acquisition Regulation Supplement (DFARS).

These standards apply to various organizations, including contractors, manufacturers, and suppliers working with federal agencies or handling CUI in any capacity.

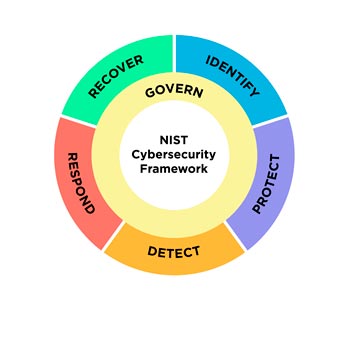

NIST five-part Cybersecurity Framework

Image Credit: National Institute of Standards and Technology (nist.gov)

PCB manufacturers often serve industries that rely on secure and precise technology, such as defense, aerospace, and healthcare / medical / instrumentation. As such, they frequently encounter contracts or projects involving CUI including:

To comply with NIST 800-171, organizations must implement robust security measures, grouped into 14 categories:

An additional non-technical requirement is to develop, implement, and maintain a security program, including policies and a System Security Plan.

For suppliers of bareboard PCBs and PCB assembly, implementing these requirements means safeguarding customer designs, intellectual property, and sensitive specifications against cyber threats.

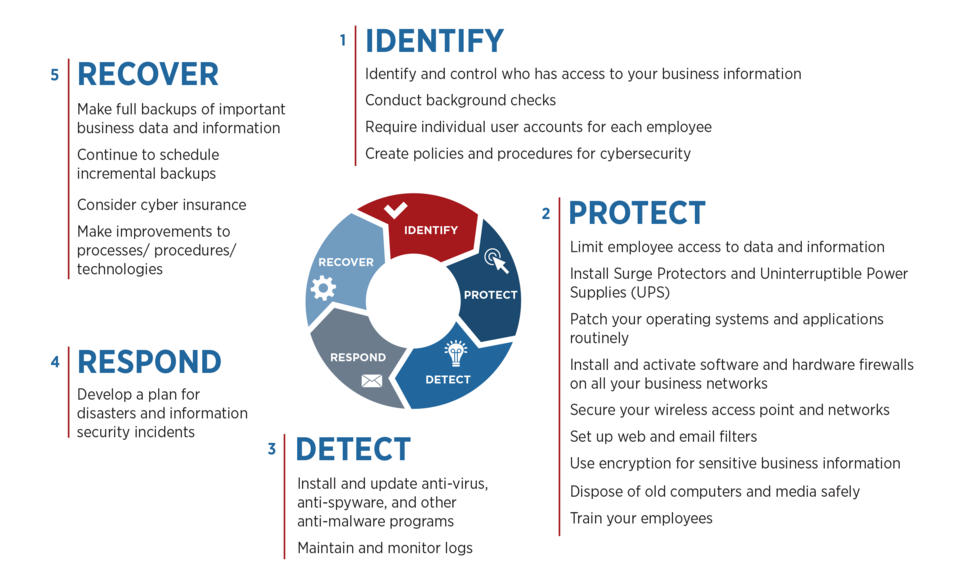

Six main pillars of a successful cybersecurity program, providing a foundation for meeting NIST 800-171 requirements

Image Credit: National Institute of Standards and Technology (nist.gov) N. Hanacek/NIST

NIST 800-171 compliance is not just a regulatory obligation but a foundation for advanced cybersecurity initiatives. The Cybersecurity Maturity Model Certification (CMMC), for instance, builds upon NIST requirements, creating a tiered certification system for DoD contractors.

The Cybersecurity Maturity Model Certification (CMMC) 2.0 program, recently finalized, refines and streamlines the original framework, introducing three distinct levels of certification to match the sensitivity of the government data involved in contracts:

The CMMC program underscores a risk-based approach to cybersecurity, ensuring contractors align with tailored requirements based on their risk exposure and the type of information they handle. For PCB manufacturers and suppliers, understanding and adopting the appropriate CMMC level is essential to meet DoD requirements and maintain trust as a secure partner.

By searching for PCB partners that have achieved NIST compliance, PCB buyers ensure they have a partner that has cybersecurity and data protection at the forefront of their processes; and will continue to do so for future compliance requirements and challenges.

Here are actionable steps you can take as a PCB buyer to vet potential suppliers - whether you’re buying for a federal contract or not:

By ensuring that your PCB manufacturing partner complies with NIST 800-171, you protect your intellectual property from cyber threats, avoid potential breaches of contract, and meet any regulatory obligations tied to your industry. Cybersecurity is no longer optional; it’s a necessity for buyers and their partners.

We specialize in providing a single-source solution for bareboard and assembled PCBs. Whether you need standard technologies or cutting-edge, advanced designs, we deliver exceptional technical expertise and innovative solutions.

Our capabilities encompass both standard and advanced technology prototypes and production runs, ensuring high-quality, multi-layered PCBs with intricate layouts, all delivered on time.

PCB School

San Francisco Circuits covers the 8 types of PCB vias including blind, buried, microvias, through-hole, stacked, & thermal vias - what they are, how they work, & where they’re used in advanced PCB design.

PCB School

San Francisco Circuits covers board-level tips for the design & layout of high-speed circuits in advanced applications.

PCB School

PCB line tracing relates to both function and safety in circuitry. We discuss the significance of careful line tracing through both clearance and creepage.

PCB School

Via tenting is the application of soldermask to encase or seal the via’s opening. A via is essentially a hole drilled into the PCB that facilitates connections between multiple PCB layers. An untented via, on the other hand, remains uncovered by a soldermask layer. The decision to expose or cover these vias carries both advantages and disadvantages contingent upon your specific design and manufacturing requirements.

PCB School

The Essential Guide to PCB Assembly Drawings: Understanding Polarities, Pin1 Marking & Anode/Cathode Markings. Learn more about understanding the XY File, component locations, & polarized component orientations.

PCB School

This article explores insertion loss: its properties, how loss occurs throughout a signal path in a system, and things we can do to minimize it.