A Flex PCB or FPCB is a patterned arrangement of printed circuitry and components that utilizes flexible based material with or without flexible coverlay. These flexible electronic assemblies may be fabricated using the same components used for rigid printed circuit boards, but allowing the board to conform to a desired shape (flex) during its application.

FPCBs are used widely in everyday technology and electronics in addition to high-end, complex completed components. A few of the most prominent examples of flexible circuits usage is in modern portable electronics, devices, hard disk drives and desktop printers.

Flexible circuits are also used extensively in other applications and industries including:

|

In transportation they are extensively used due to their improved resistance to vibrations and movement.

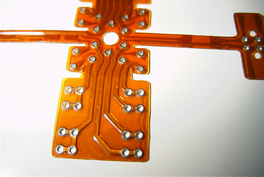

Flex Cover

Photo Credit: Robert Tarzwell

We can turn your flexible PCB manufacturing order in as quick as 24 hours.

Call us at 800.SFC.5143 or get an instant PCB quote.

We are ready and eager to turn your concepts into reality.

| Specifications | Capabilities |

|---|---|

| Drill to copper – Outer layers | 8 mil |

| Drill to copper – Inner layers | 10 mil |

| Copper Thickness | 0.5 oz - 4 oz |

| Minimum Hole Size | 0.004" |

| Minimum Trace/Space | 0.003"/0.003" |

| Minimum Pitch | 0.5 mm |

| Copper to board edge | 0.007" |

| Coverlay Opening | 0.003" |

| Coverlay Web (Kapton) | 0.006" |

San Francisco Circuits can provide heavy copper flex circuit boards that can also be coupled with flexible thin copper layers designed to handle heavier power currents. Your heavy copper boards can be built with flex portions for lower voltage additions and applications.

Heavy Copper Flex PCB

Photo Credit: Robert Tarzwell

Whether you're looking for a double sided flex circuit or complex multi layer flexible PCBs from your flex PCB manufacturer, we can provide you with the guidance, expertise and capabilities to bring your concept to reality. Multi-layer flex boards are being used more often in electronic applications for higher speed performance but at a loss of flexibility. Single-sided or double-sided multi layer flex PCBs can be designed in unique and complex layouts, with a much greater possibility of combinations compared to FR4 board design. Just as multi-layer FR4 boards, the multi layer FPCBs can be designed using blind and buried vias as well as plated through holes (PTH).

Our strong network of manufacturers can push the limits on PCB fabrication technology, with very fine traces, RF PCB / HDI PCB technology and more!

The primary benefits of flexible circuits compared to traditional cabling and rigid boards include the following benefits listed below.

Flex boards benefits include:

Flex PCB disadvantages also exist:

To ensure the highest quality of your flexible circuit board, we also offer thermal cycling and shock testing to ensure proper usage in the desired environment. PCB burn in testing is available for all SFC-provided boards. We can also provide PCB assembly for all circuit board types.

Flexible Circuit Boards

Photo Credits: Robert Tarzwell

Electronic devices have taken upon a prominent part of our everyday lives. The extensive range of devices from cell-phones to servers, regardless of their sizes and uses are now being designed to be flexible, lightweight and efficient. While they all come in diverse shapes, sizes and functionalities, there is one thing in common - they include flexible printed circuits boards.

There are a number of advantages using flex PCBs. Flexible circuit boards are specifically designed to save room and improve flexibility in meeting smaller and high-density mount designs. They also reduce the items in the overall assembly process and enhance reliability of the PCB.

The other advantages of flex PCBs are:

Because of a strong network with the best flex PCB manufacturers, San Francisco Circuits can provide our customers with flex printed circuit boards with a great variety of technologies, from simple single-sided flex boards to complex multilayer flex, from commercial applications to high reliability military PCB. We can turn your flex PCBs as fast as in 24 hours, depending on technologies. If you’re looking for production quantities of flex or a flex pcb prototype, SFC’s experts are there to assist with every step of the process at the best value.

Call us at 800.SFC.5143 or get an instant PCB quote. Tell our experts what you need and we will provide you with the right PCB production and assembly solution. We are ready and eager to turn your concepts into reality.